-

网站客服咨询客服1

-

服务热线:

021-20919220 -

网站客服咨询客服1

服务热线:

021-20919220

性能特点/Product features

※ 本设备采用悬臂式结构,关节臂机器人悬挂于横梁上,可水平移动,可升降,适应不同规格的工件,适用范围广。

※ 设备可将工件翻转使焊接面呈水平放置,实现水平焊接,有利于焊缝质量提高,坚守焊缝缺陷。

※ 采用先进的视觉传感技术,对焊缝进行非接触测量,实现管口和焊缝的快速准确定位,完成高质量焊接。

※ 可实现圆管或非圆形管与管板的焊接、筒体端部与管板环缝的焊接、钢筋与管板的焊接等功能。

※ 智能化数字控制系统,全自动运行,操作简单,降低了工人的劳动强度和对工人操作技能的要求。

※ 读图功能:可读取*.dxf管板排列和尺寸图纸信息。

※ 焊机通讯功能:自动调取和设定焊接工艺参数。

※ 记录焊接生产数据功能,满足生产管理和质量追溯。

※ The device adopts a cantilevered structure. The joint arm robot is suspended on the beam and can move horizontally. It can move up and down and adapt to different specifications of the workpiece. The scope of application is wide.

※ The equipment can turn the workpiece to make the welding surface horizontal, achieve horizontal welding, which is conducive to the improvement of weld quality and adhere to weld defects.

※ Using advanced visual sensing technology, the welding seam is measured without contact, and the pipe mouth and weld seam are located quickly and accurately, and high-quality welding is completed.

※ It can realize the welding functions of circular or non-circular tubes and tube plates, welding of tube ends and pipe plates, welding of steel bars and pipe plates.

※ Intelligent digital control system, fully automatic operation, simple operation, reduced the labor intensity of workers and workers 'operating skills requirements.

※ Reading diagram function: readable *. Dxf sheet arrangement and size drawing information.

※ Communication function of welding machine: automatic adjusting and setting welding process parameters.

※ Record welding production data function, meet production management and quality traceability.

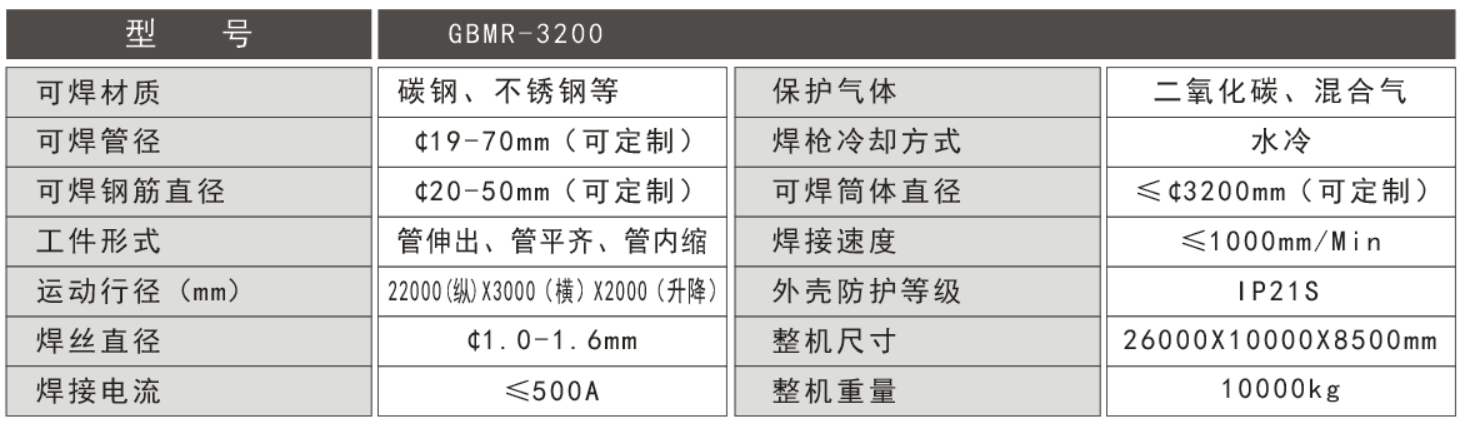

技术参数/Specifications

适用范围/ Scope of application

本设备是为大型管子管板焊接而设计的,适用于大型筒体的管子管板焊接、筒体端面环缝焊接、钢筋与管板焊接。主要应用于锅炉、压力容器、核电设备等行业.

The equipment is designed for welding large tube boards, and is suitable for welding large tube boards, welding of tube end joints, and welding of steel bars and pipe boards. Mainly used in boiler, pressure vessel, nuclear power equipment and other industries.